PRODUCTION

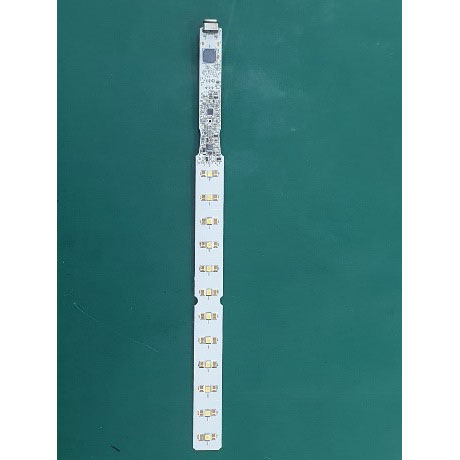

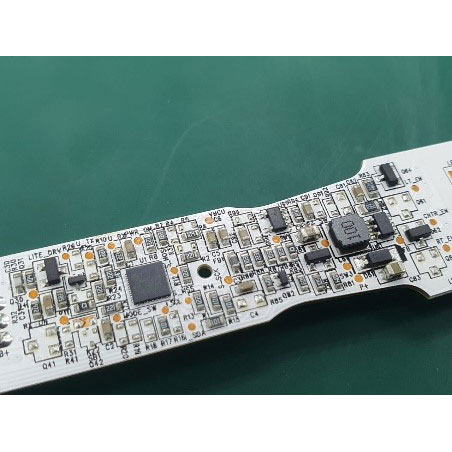

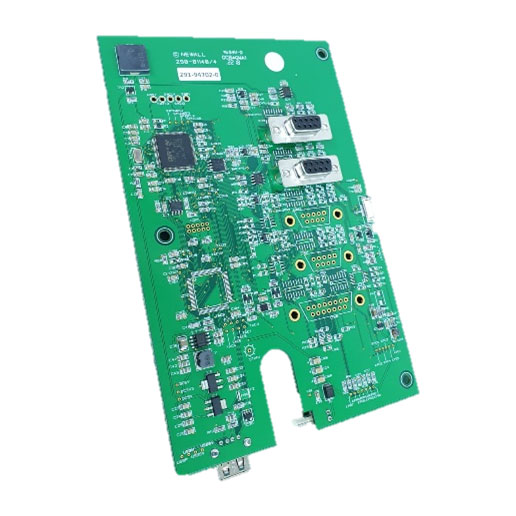

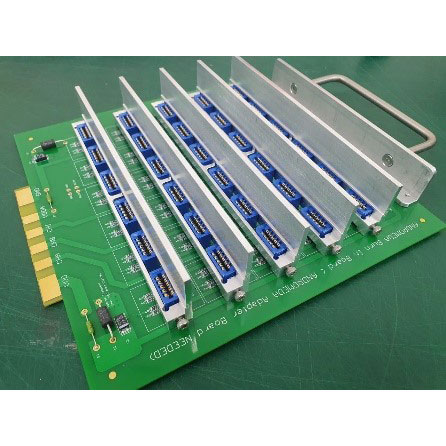

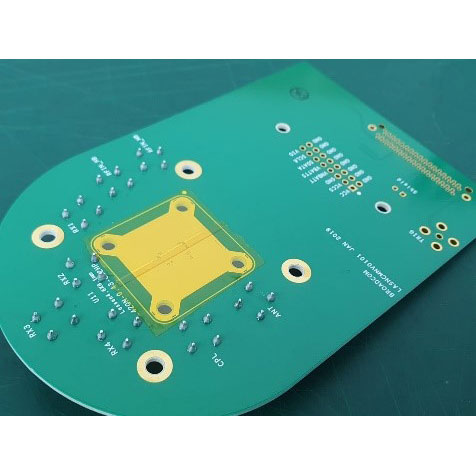

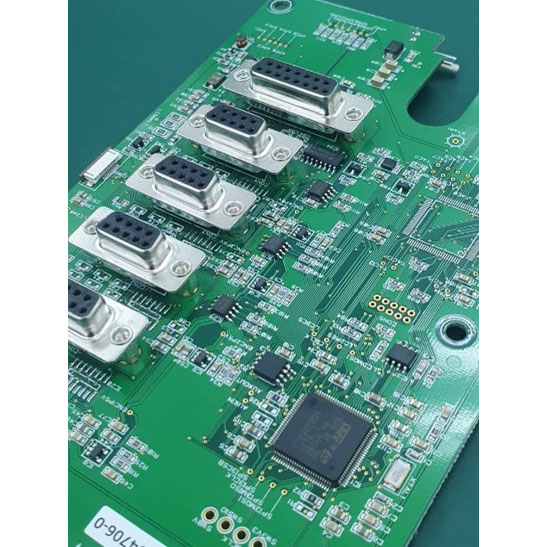

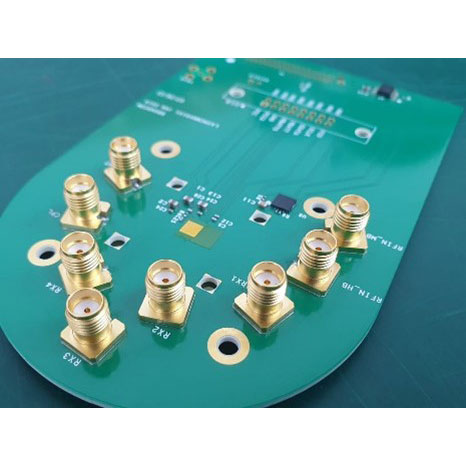

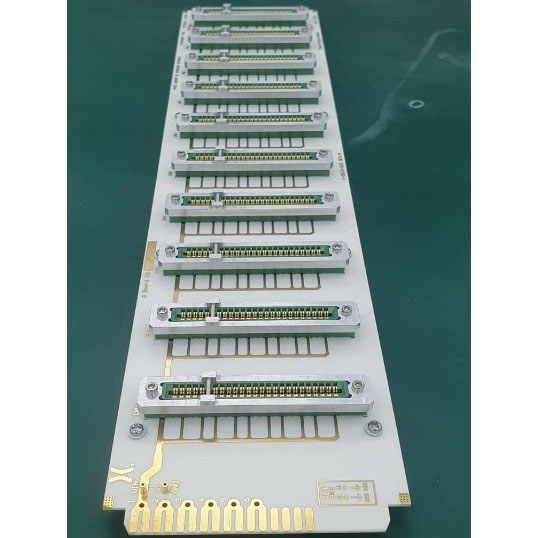

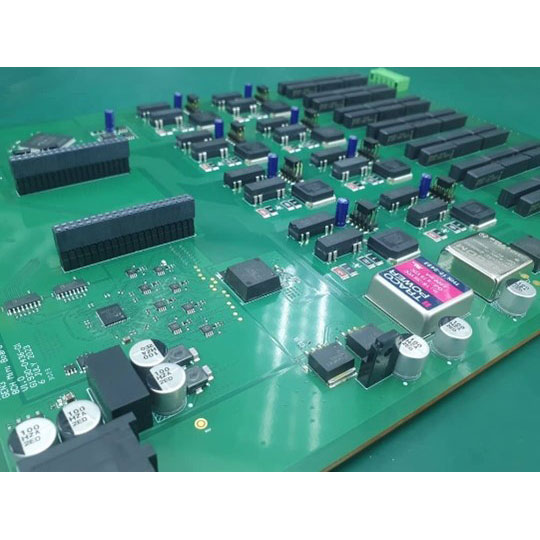

PCB Assembly

There are consists of 3 SMT lines with the below equipments

Flexi Mouter

Model no.: AdVantis AX-72

Flexi Mouter

Model no.: GC60 HSCB032

Chip Shooter

Model no.: KE-2050L

Chip Shooter

Model no.: KE-2060L

Chip Shooter

Model no.: KE-2070L

Reflow Oven

Model no.: 820A

Off-Line Vacuum Vapor Phase Reflow

Model no: VP800

MPM Accuflex Solder Printer

Model no.: Acculex/UP2000

MPM Accuflex Solder Printer

Model no.: DSL-1200

Board Tester

Model no.: TR-518FR

Automated Optical Inspection (AOI)

Model no.: KY8030-2XL

Automated Optical Inspection (AOI) SAKI

Model no.: BF-FrontierII

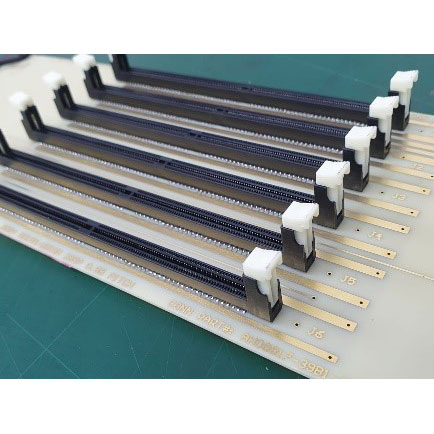

For the through hole component, there are Wave Soldering

Selective Wave

Model no.: SEL-32

Wave Soldering

Model no.: BF-06FST

- The company designs, manufactures and markets both front and back-end equipment and systems used in the testing and assembly of PCB.

- Providing high quality products and services that fulfill the price and quality requirements of our customers.

- Create opportunities for achievement and personal growth for our employees as well as to enhance value for our shareholders.

- Highly skilled production staffs and highly skilled troubleshooting engineers

- Strategic factory location (vicinity to MNC & SMI factories)

- Adequate quality control measures and monitoring

- SMT assembly line is capable of handling 0201, fine pitch 0.3mm BGA, flexible PCB.

- Innovated process to achieve reduction in manpower cost and production time with consistent quality.

- Lead-Free & RoHS compliance

Advantages of our PCB Assembly electronic product box build

- 95% skilled workers, one person for one post. The workers are trained by strict team leaders responsible for on-site prevention and correction; employee skills are guaranteed.

- Team leaders patrol the production line throughout the whole process, responsible for timely statistical analysis of defective items in the assembly process, improvement, and promotion of quality.

- Implement strict SOP operating standards, including content items such as operating methods, IPC quality standards, tooling and equipment, and statistical analysis.

- On-site QC 100% full inspection, QA conducts random inspections in accordance with AQL standards, and timely discovers and controls defective items in the process.

- Before the product is packaged and shipped, the quality department conducts OBA unpacking inspection.

- The production line is equipped with complete operating equipment, such as electric screw drivers, magnifying equipment, air-gap torsion meter, dispensers, E-test fixture, and various auxiliary inspection equipment.

- Strict material area division in the assembly line to prevent mixing of materials and boards.

- Have experience in box build sophisticated and complex products.

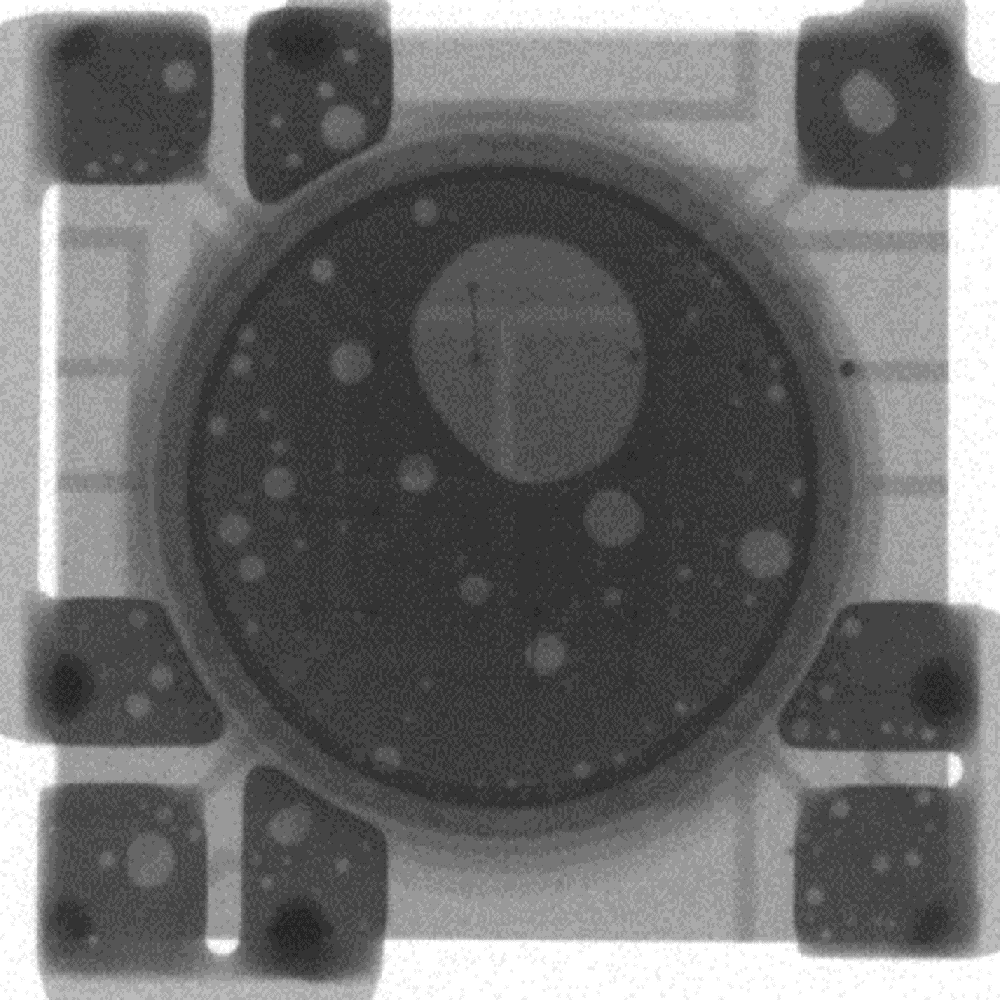

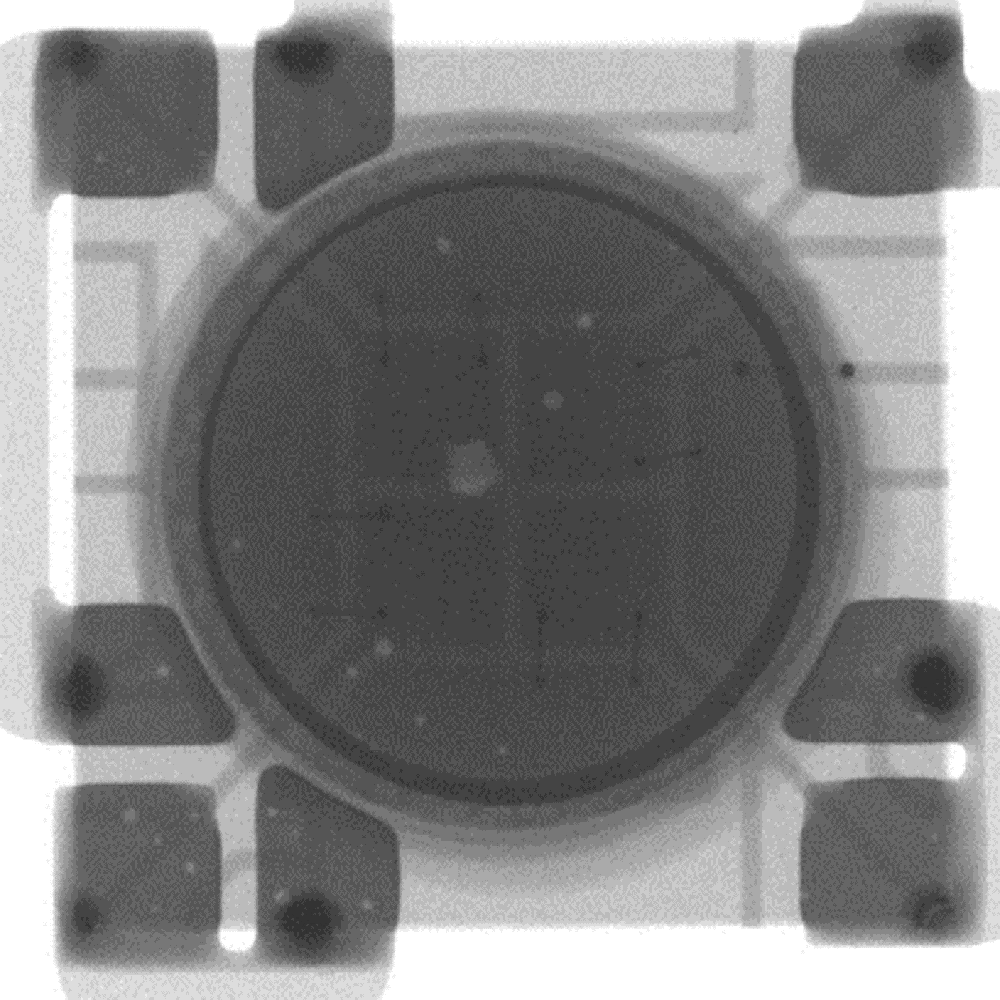

| LED Emitter attachment to MCPCB | Convention Reflow

|

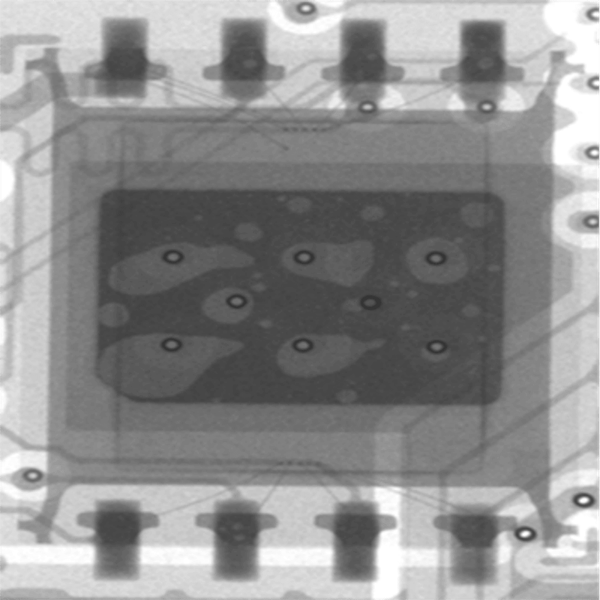

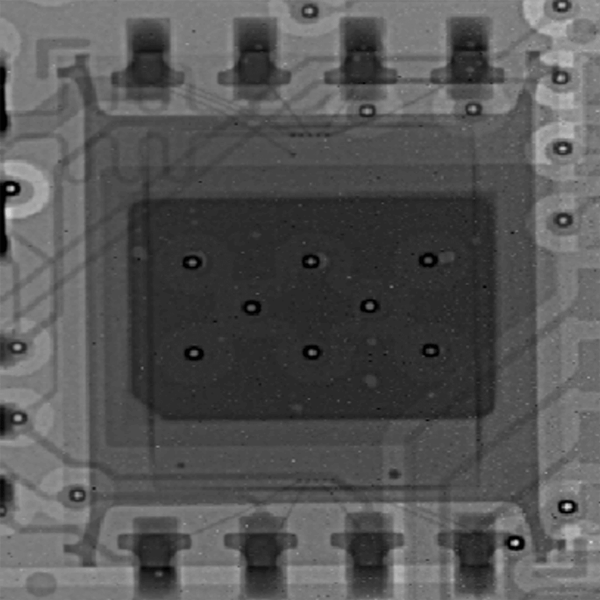

EPS’s Vacuum Reflow

|

| LCC with thermal pad attachment to PCB |  |

|

Innovative solution for the lowest solder void formation

| Item | Item Name | PCBA Capability | |

|---|---|---|---|

| 1 | Part Source | Consigned/ Kitted | We prefer you supply all the parts for the PCBA services. In this case, please send us all the components with BOM file and detailed packing list indicating item number, customer or manufacturer’s part number and quantity in kit. |

| Turn-key | With our wide and powerful network of parts sourcing, we offer Turn-key PCBA service. We do not mark up on the parts cost. Considering the big price gap between different suppliers, we only source from reliable suppliers who may have no price advantages. We will always ask for your approval before making any decisions. | ||

| Partial Turnkey/ Combo | This is our regular practice which you offer the main devices and components, while we source the rest for you. Just like the Turn-key service, we will ask for your approval on every detail of the parts concerning price, quality and availability. | ||

| 2 | Minimum Order | Our minimum is as low as 5 pieces. We do not want you to pay for what you do not need indeed to save you money. | |

| 3 | Component Package | We accept parts in Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk. | |

| 4 | Board Dimension | Max Board Size: 450mm x 550mm (We can assemble as small as 5mm x 5mm to 350mm x 1020mm) |

|